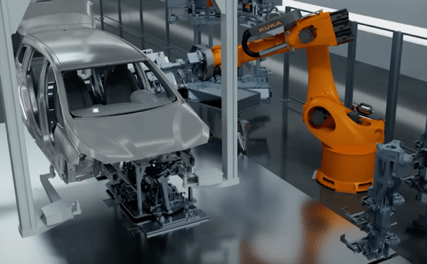

METAVERSE IS THE MOST EFFECTIVE IN

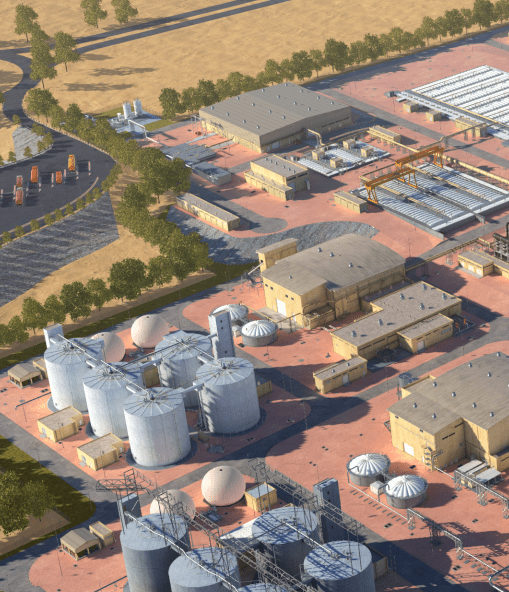

PRODUCTION MANUFACTURING

Machinery vehicles

Planes

Vessels

Parts

Food

Goods

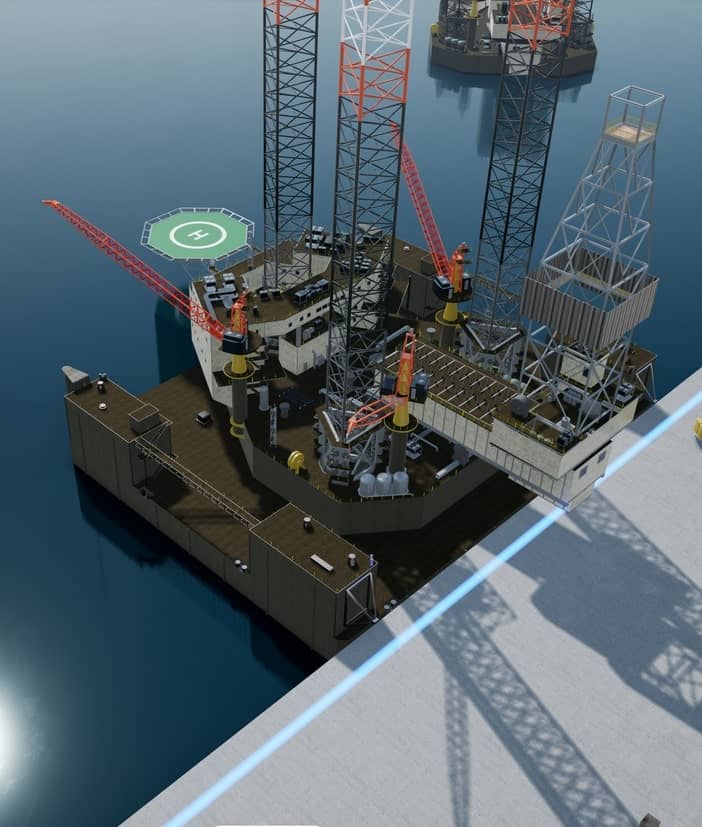

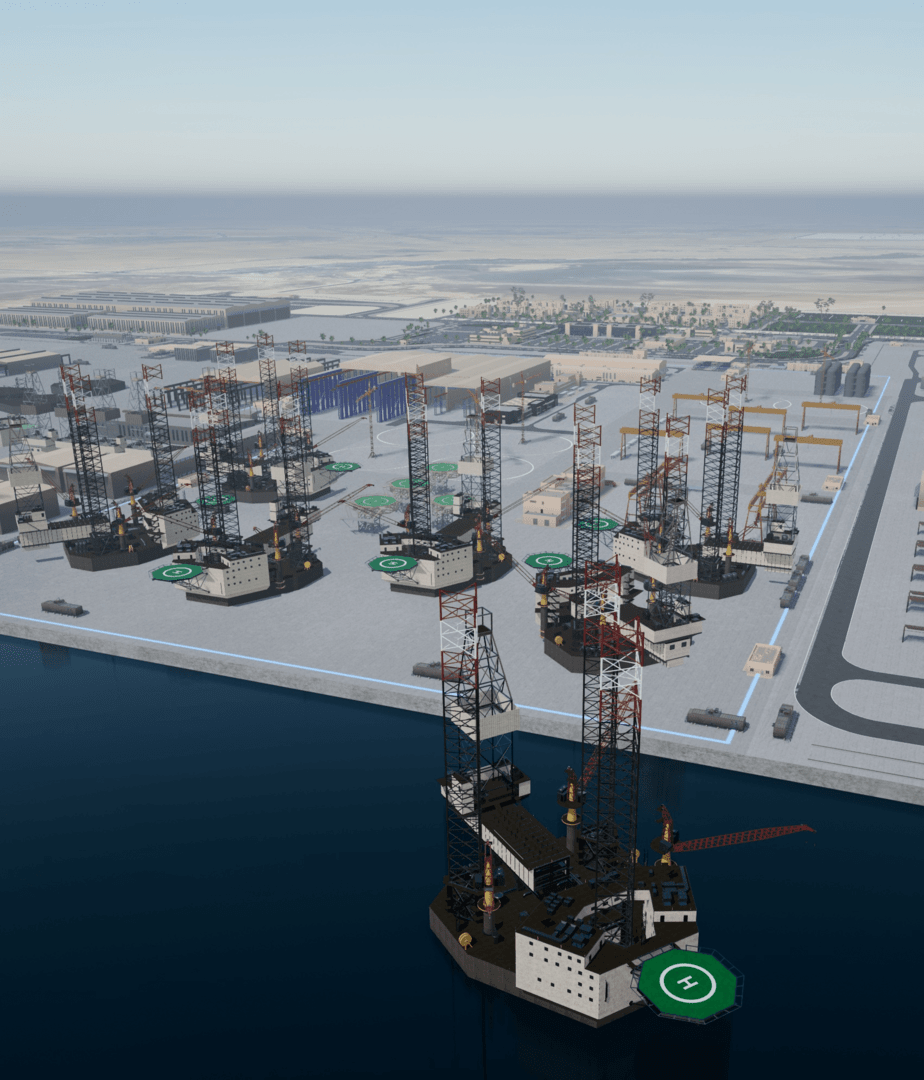

SERVICE / RESOURCE PROVIDING

Water

Gas

Electricity

Oil

Petrol

Packing

Sorting

Delivering

Retail (Storing/Logistics)

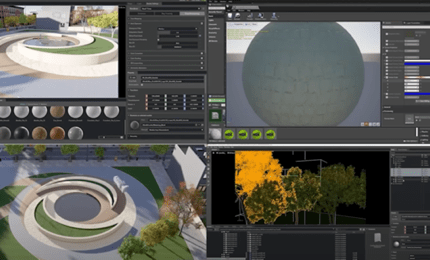

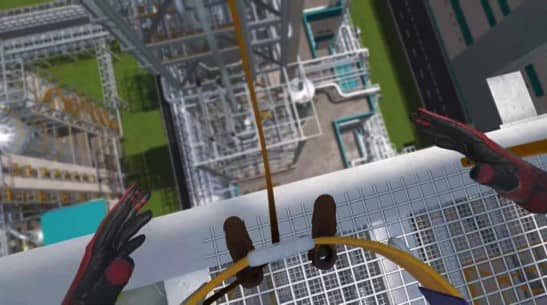

CONSTRUCTION

Buildings

Facilities Management

(hotels, Stadiums etc)

(hotels, Stadiums etc)

Site Planning

SMART CITY

City Planner

One Frame for Smart Analytics