Slicing through waves a jumbo ship is moving ahead full sail to the dock. People can’t take the eyes off of the ship waiting for the next captain’s move with bated breath. Is he a newbie? Did something go wrong? Are we looking at the reason for today’s overtime? Anyway, the overspeeding ship starts to turn clumsily ignoring port operator’s radio distorted screams and shouts, as inertia steers the ship and a big wave pounds on the mooring — kaboom! The ship kisses the concrete shore. The next thing you see is a loading metal crane gently hugging the ship.

All this could have been avoided, should a system similar to car parking sensors alerting the driver about obstacles – curb or garage walls – be installed on vessels to do the same job for the skipper. A video recorder would be useful for documenting all events as well, if scaled proportionally, of course, to the size of large ships and moorings. In fact, all ships have such equipment to video ships approaching the shore and mooring, but this is barely enough. What we really need here is the next level mooring assistant familiar with all marine peculiarities, since natural forces influence sea travel and mooring greatly, unlike ordinary parking.

The ship always hits the mooring. It is just possible that the mooring perfectly maintains and serves ten ships in a row, but can’t survive the eleventh and falls apart, thus triggering a series of unfortunate events and causing port to lose money.

- Firstly, a mooring costs a lot. If pipes, port facilities, and loading cranes are damaged in an accident, costs grow proportionally.

- Secondly, every ship is on a tight schedule, so it has a narrow window for docking – 30 hours, for example. If a port manages to maintain and serve a ship within the deadline or earlier (25 hours, for example), it receives a bonus from a shipowner. Delays may occur as well, which means that the port owes a penalty. A broken mooring causes a sea of changes in the port’s schedule, and service delays become inevitable.

- Thirdly, the port has to prove to the insurance company that it is not guilty of messing everything up. How to prove it? Captains do not feel like providing records from their ship systems. In a worst-case scenario, the port loses more money paying for the damage.

Thus appeared MOORiNET, a solution for vessel mooring and berthing designed to prevent any massive accidents involving ports or moored ships. MOORiNET system warns about undesirable ship movement and possible collisions to prevent ship or dock damage, oil hose or loading arms breaking, spread of hazardous and noxious substances. Remember those car parking sensors? MOORiNET is its big brother: a marine garage-scale mooring sensor keeping it safe from crazy skippers. How do you like that, Elon Musk?

Port control over vessel maneuvers

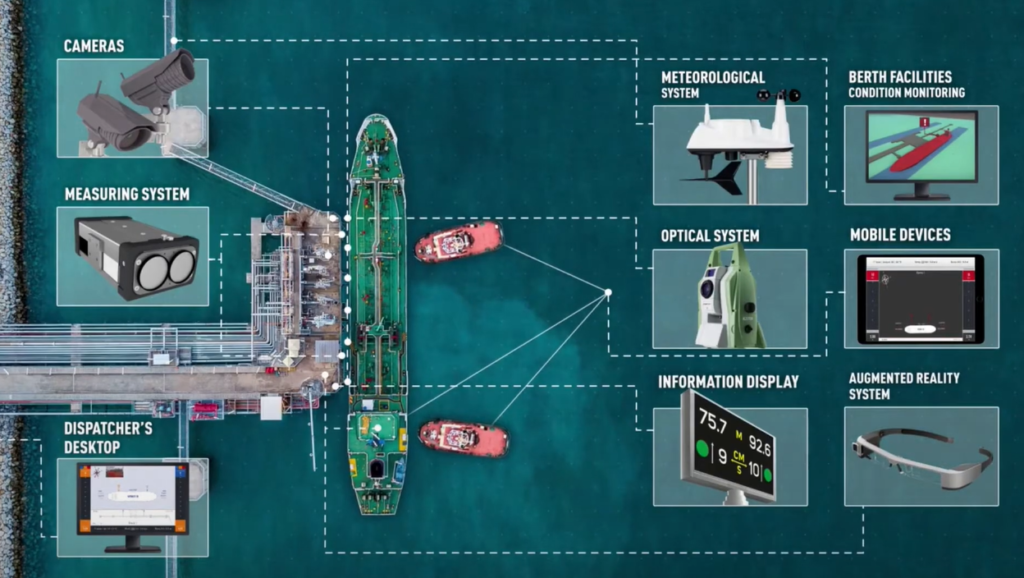

MOORiNET monitors where and how the ship is going and helps it to dock safely. The sensors detect various weather conditions and transmit the data to the port operator who supervises mooring rules. Weather sensors measure wind, wave, and visibility. A meteorological station monitors the outside temperature, atmospheric pressure, and the sea surface height. When a ship approaches, laser rangefinders and surveillance cameras automatically start monitoring the bow and stern using machine vision. The ship is captured from 300 meters, and the closer the ship gets, the more accurate the data are. The berth has a system that measures the impact during the mooring.

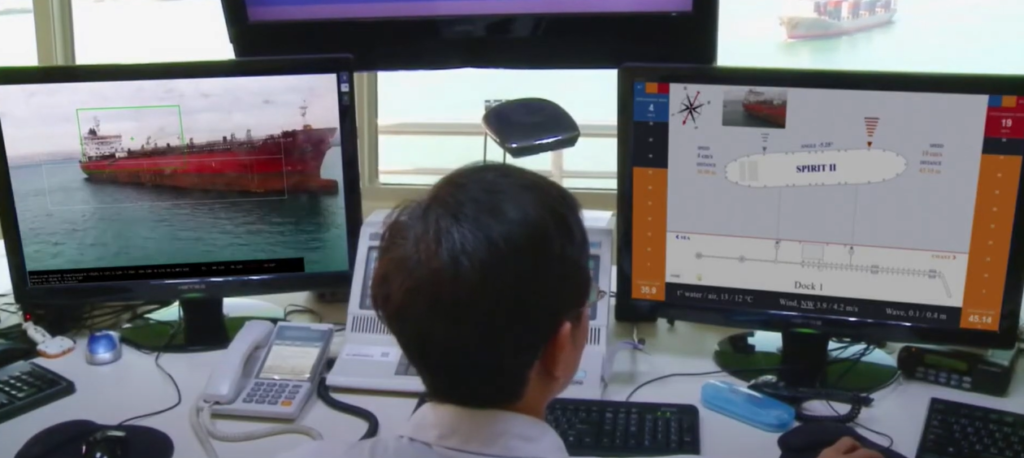

Therefore, an operator enjoys full port visibility. The ship’s speed is monitored as well in real time and displayed at the operator’s dashboard. Each vessel is highlighted with a color representing speed safety level range. In the case of any violations, the operator proactively warns the ship to take the situation under control. Should an accident happen, all sensor data records will be available to help investigate, whether a huge wave caused an accident or if the ship was violating mooring rules and overspeeding.

Loading accidents

There is a rule, and the rule says: Once the ship docks, the port is responsible for whatever happens to it then. Now, picture this: a moored ship is being loaded with oil. The vessel gets heavier with each new ton, and all this pressure goes down on the mooring… To keep the mooring from being depressed, load binders are used. These are automatically controlled metal devices to tighten chains holding the ship’s bow and stern fixed. Many ports shut them off, as they can loosen or tighten the ship too much. Usually, somebody controls load binders using nothing but natural intuition and experience. Sadly, either human errors caused accidents or the perfect storm occurred with all its wind, fog, sand in the face, the sun hurting the eyes, and heavy snowing in the northern countries. Chains break apart, the oil hose follows, and the hazardous chemical spills on the sea surface. Here is when oil spill detection solutions come in handy.

MOORiNET can be integrated with a load binders system. The algorithm uses video analytics and laser rangefinders to detect a slightest movement of the ship and automatically alert a person responsible, so that this person either loosens or tightens the chain. The same applies to the oil supply system.

Harbor pilot helper

There is a MOORiNET version designed specifically for harbor pilots. An Android app gives a pilot all necessary information such as the speed at the ship’s bow and stern and the weather. The app connects to the ship’s system via a connector and synchronizes data with the MOORiNET at the mooring, thus providing the port and the ship with consistent information for better safety.

Read more:

- How ifalcon foreman speeds up clock-in five times and improves attendance control at construction site

- Innovative medical kiosk for three-minute health check

- Industry 4.0 to reduce the number of accidents at oil and gas facilities

For more fresh news, subscribe to our newsletter