Any industrial inspection solves three main tasks: data collection (photos of objects), analysis (identifying defects and abnormalities), and reporting. Today, Pavel Tatarintsev will talk about ATLAS – image analysis and automatic reporting system that covers the most labor-intensive industrial inspection tasks.

Naturally, ATLAS is not the first solution on the market that analyzes photos and automates reporting, but its unique easily trainable AI module makes it a truly handy and unparalleled tool.

How I taught ATLAS to find bushes in the desert

I will describe the module operation using my own user experience as an example. One weekend, I decided to go to the desert and, just for fun, teach my ATLAS to recognize bushes. It was an easy, interesting, and clear process. I used a standard laptop with installed UgCS and ATLAS software, as well as a 400g DJI Mavic Air drone with a built-in wide-angle camera. This is a small, quite popular and affordable drone.

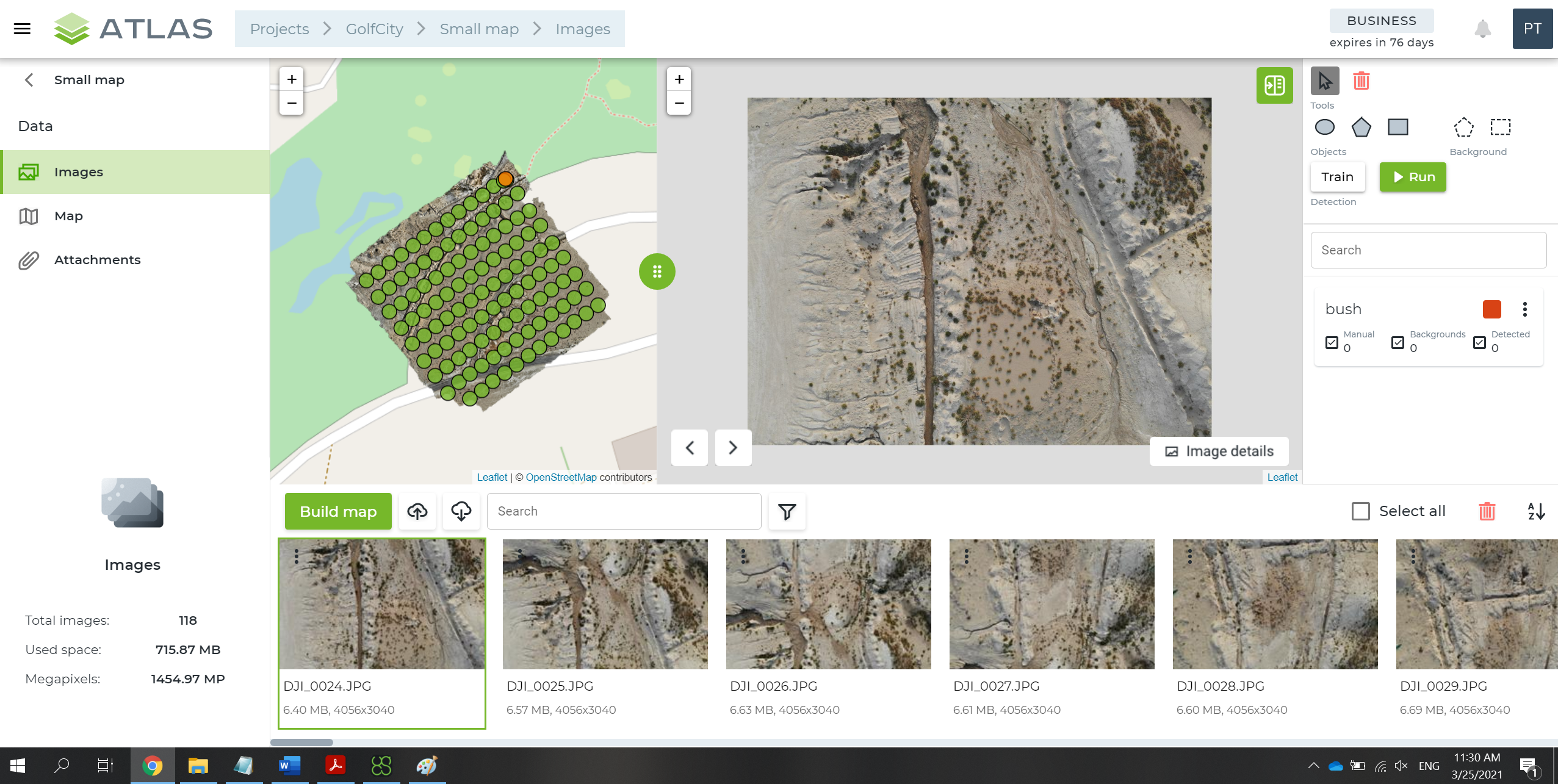

First, an engineer needs to draw a route for a drone in UgCS (below is the screenshot of my drone’s route). I set the frequency of taking photos and the following parameters. It took my drone 15 minutes to fly around three hectares.

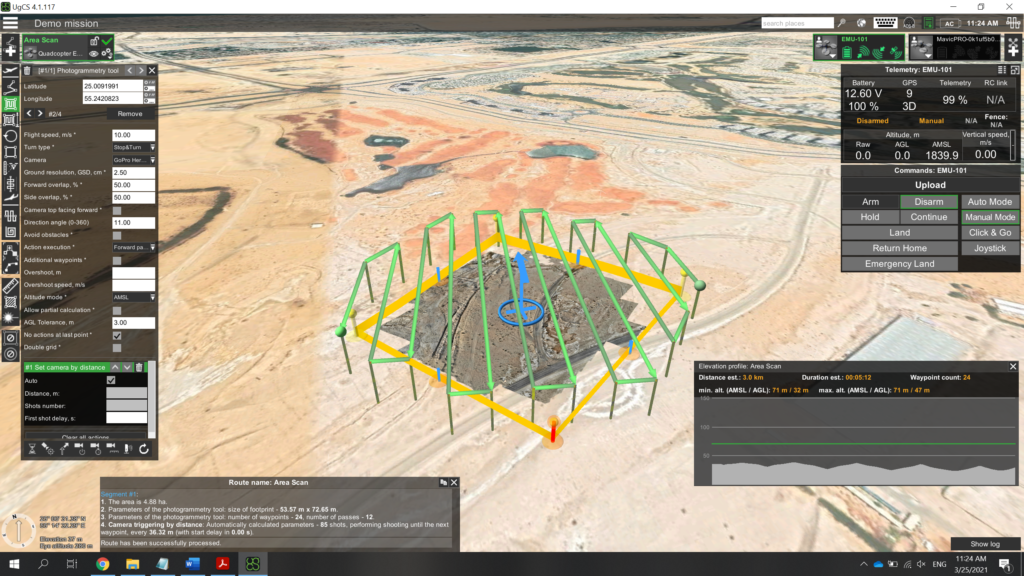

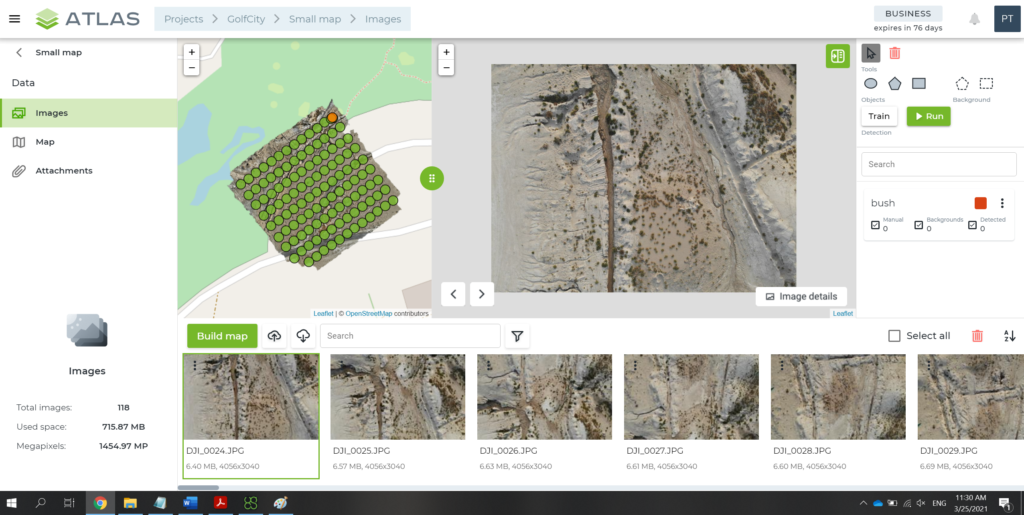

As a result, I got approximately 100 photos for analysis.

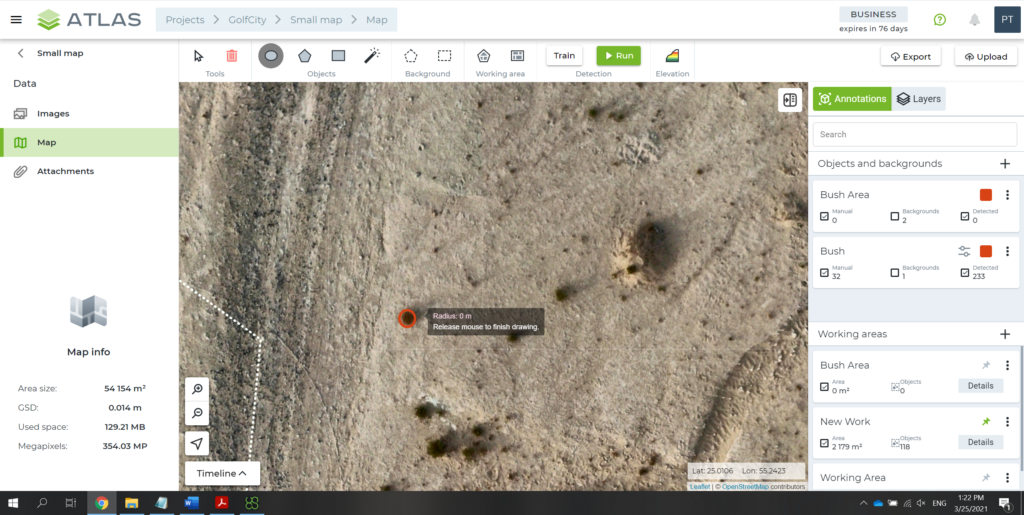

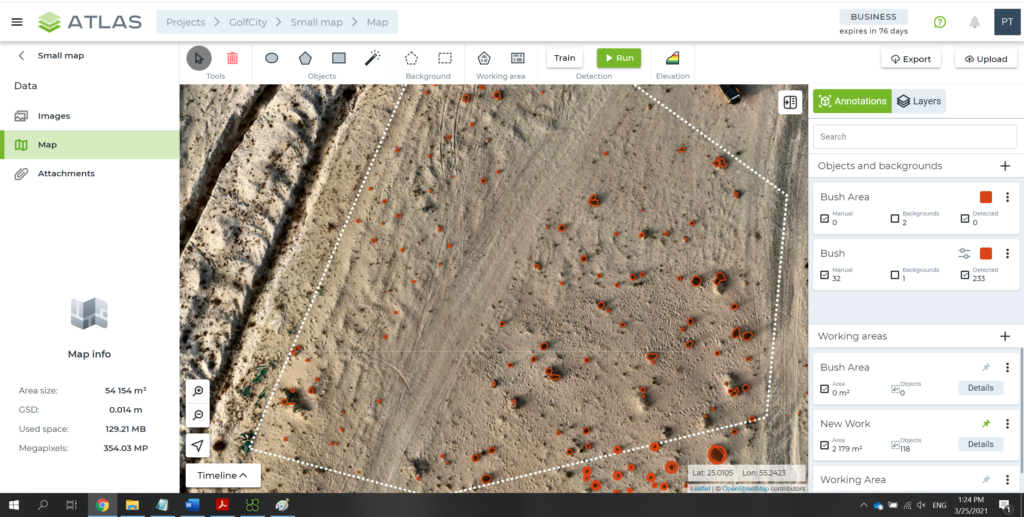

I uploaded the photos to ATLAS, which, in 5 minutes, created an area map with the relief. As I wanted ATLAS to learn how to find bushes, I then used a marker to outline the bushes on some 20-30 photos and launched a search by photos.

In 20 minutes (including AI training and photo search), I got my result. The program managed to count not only the number of bushes, but also (if needed) the total area covered by them. Indeed, you can set any parameters and reporting targets for this flexible and intelligent solution.

It is efficient, isn’t it? I believe very much so. Now imagine that the solution can find not only bushes, but also cracks on roads, rust on metal structures (for example, rusty spots on ships), oil spills, and any other things or flaws that the built-in AI can learn.

Is it easy to teach ATLAS AI for drone industrial inspection? Depends on what you want it to learn. When it comes to rusty spots on the pipe surface, all it takes is just a few photos with outlined spot examples. But if you need AI to find a green car in the green leaves, it’s more challenging and the system will need more examples for training.

ATLAS and industrial inspection tasks

Let me tell you the story of one of our customers (without mentioning its name). Our customer bought a ‘fixed-wing’ drone (a plane-like model that can fly continuously over long distances, collecting necessary data) and had a camera installed on it to shoot the sea surface. The drone flew and brought back 12,000 photos to be analyzed for oil spills. Just imagine how long it would take to manually analyze and document all these photos. Plus, oil film is often very difficult for the human eye to see on the waves. Nevertheless, the customer successfully addressed the challenge opting for ATLAS that was taught by an engineer to promptly find oil spills on photos.

This solution is also used to fly around and inspect the condition of oil pipes and production facilities, survey vegetation, as well as scan object surfaces, soil, and asphalt. The solution can be easily applied virtually in any sector and for any task. You can even set it the task to not only looking for defects but also rank them by hazard.

This is how artificial intelligence facilitates inspections and ensures control over the safety of both facilities and the environment. All you need to do is ‘explain’ ATLAS what task you want it to solve.

If you have any questions about drone industrial inspection, please go to the solution page on our website, subscribe to my blog, or message me on LinkedIn.