What is VR training simulator?

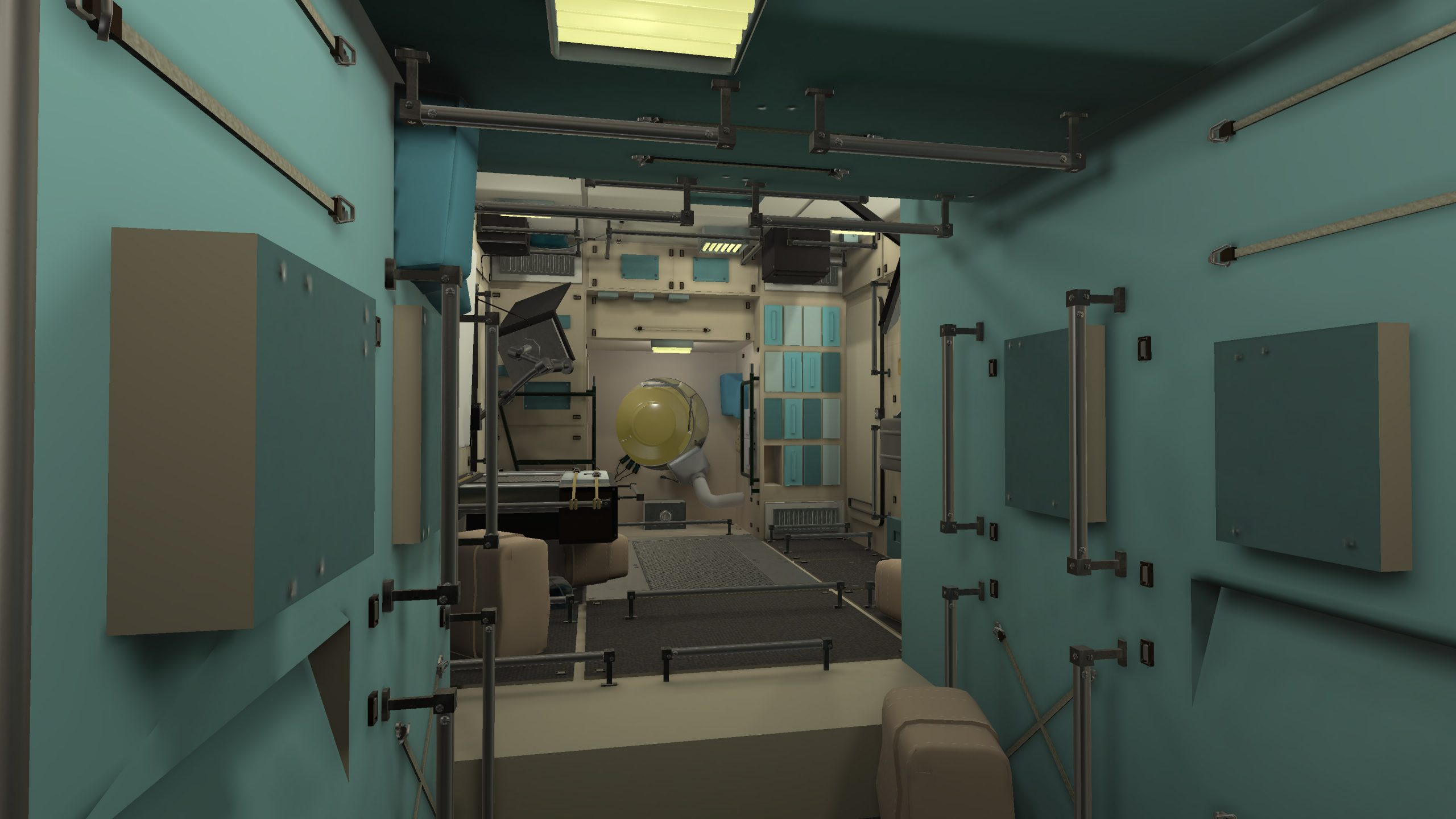

VR training simulators provide a realistic experience with simulated work environments and allow training, practicing and assessing knowledge of safety procedures in a risk-free immersive learning setting.

Such trainings are the safest and most effective in training personnel of industrial enterprises to follow safety protocols. They help reduce injury rate, equipment downtime, and in case of emergency save lives of employees.

VR training simulator is a virtual reality app developed in line with an emergency response procedure and staff training methodology as prepared by the specialists of the customer’s training center. During a VR training employees obtain necessary knowledge and skills and pass tests in a computer simulation, with the test results being available for the supervisor.

TRAINING SOLUTIONS COMPONENTS

VR trainings

Visualized production processes with training and testing modes

Equipment and infrastructure

Designing and outfitting training rooms

Integration with enterprise IT systems

Enterprise training systems, information security and enterprise data transfer systems

Introductory personnel training

Training in using VR hardware and software

75% Retention rate

Trainings on VR simulators increases the retention rate of critical knowledge and skills of staff up to 75%

30% Work speed

VR-simulator improves by 30% the speed of the engineers

96% Accuracy

VR-simulator helps professionals assess the risks of errors and increases their accuracy up to 96%

VR trainings can be tailored to various platforms: PC, VR glasses and headsets, industrial VR systems or multi-user devices with VR support. Each scenario differs in terms of user immersion, content adaptability for mobile use, and the quality of graphics.

USE CASES

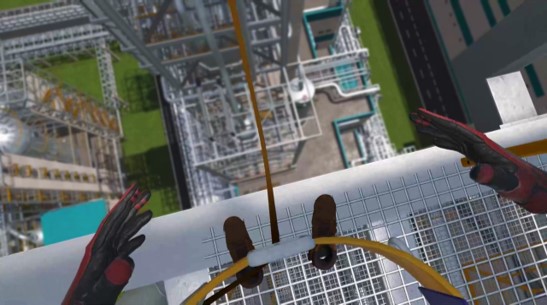

VR training simulator for working at heights

Case study

Objective: Find a training solution for reducing injuries when working at heights and lifting operations, a compact and user-friendly instrument for testing knowledge and training workers in the field

Solution: Pre-project assessment and development of a VR simulator for training and testing safety knowledge on working site

Outcome: The simulator enabled effective training and testing of workers' knowledge at construction sites

VR training simulator for working with electricity

Case study

Objective: Find a more effective training solution for electric staff training

Solution: Pre-project assessment, development of functional and technical requirements, simulator feasibility study, VR simulator development and testing

Outcome: The project showed to the company's top management that such VR simulator will boost the electrical engineering training efficiency and, if scaled to multiple locations, will cost much less than its physical alternative

Operator training simulator

Case study

Objective: Develop a training that would help reduce planned turnaround time, abnormal situations and optimize advanced process control

Solution: Pre-project assessment and development of a VR training integrated with OTS and MTS, 3D model of the plant and digital twin of one piece of equipment

Outcome: The VR training solution helps improving the quality of personnel training, reducing the number of man-made mistakes through repeatable training and enhancement of worker’s abilities through the state of the art VR training, and achieve cost-saving through the above effectiveness

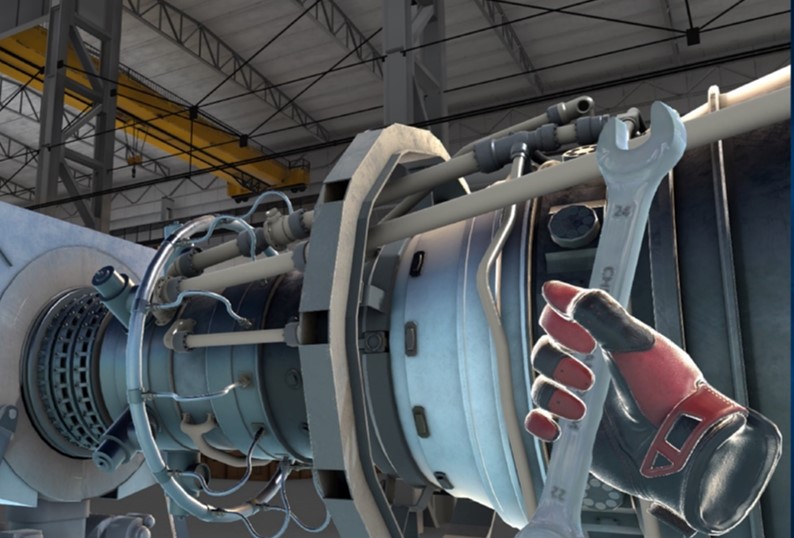

VR training simulator for equipment operation and maintenance

Case study

Objective: Develop training solution that would allow to improve training results through a better understanding of how equipment works

Solution: VR visualization of the compressor and other related technological processes

Outcome: VR simulator is used for training. The simulator provides clear visibility of the equipment, reference information, 'X-Ray' mode to observe internal machine parts without disassembling, etc.

WHY CHOOSE NNTC

- We help companies reduce the likelihood of production downtime, reduce the risk of incidents and accidents by practicing skills in virtual reality

- Expertise. Unique expertise in the market of virtual and computer simulators - our team includes experts in the field of industrial safety, development of personnel training methods and computer training complexes

- Made for you only. The simulators that we develop will be your intellectual property

- Our products meet the high requirements of information security of industrial facilities

- Full support. For us the projects ends only when you are completely satisfied with the result

Videos and images

Tell us about your interest

Please fill out the form and our experts will come back with suggestions for solving them