The majority of business leaders (63%) surveyed by PwC claimed that technologies of the Fourth Industrial Revolution (4IR) provide protection against an economic downturn. But how to find your way around this strange and seemingly unmanageable concept? Be brave, and I’ll show you a way in this blog!

What is 4IR?

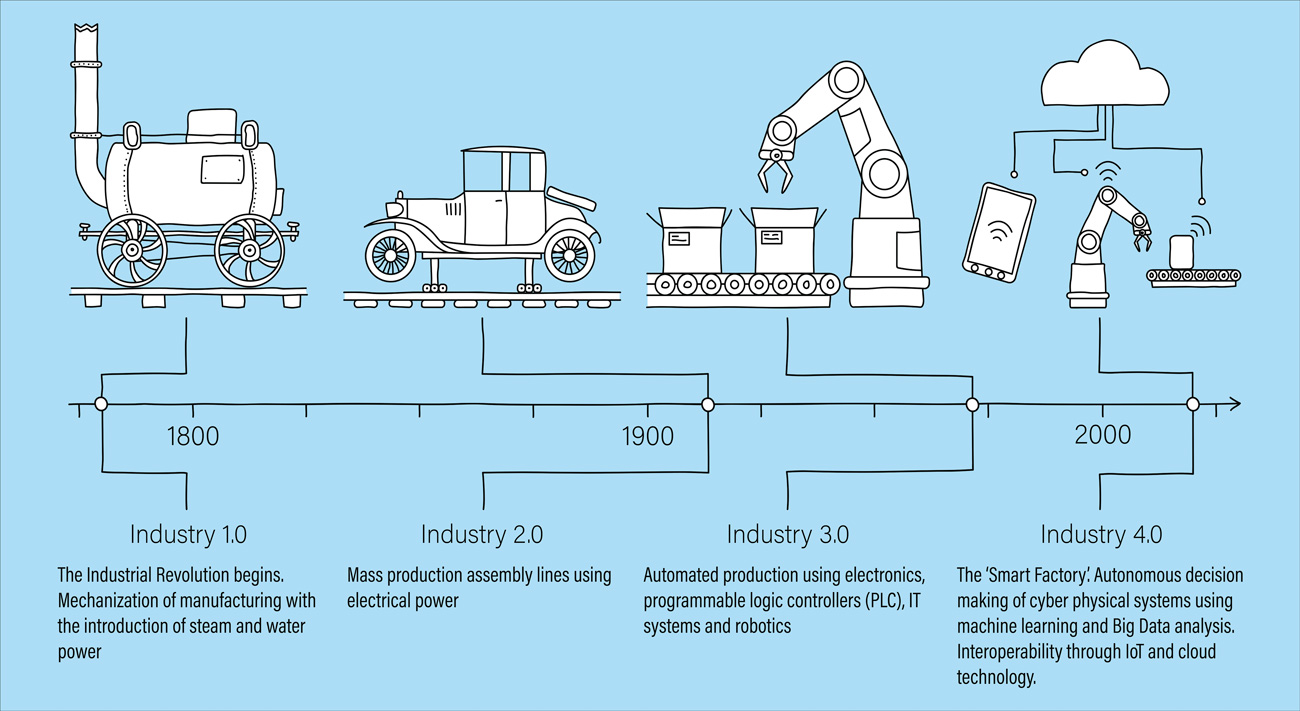

4IR became a hot topic a few years back when the world realized how technologies impact everyday life and innovations skyrocketed, giving an optimistic view of the future coexistence of humans and machines.

The Fourth Industrial Revolution is building on the Third, the digital revolution that has been occurring since the middle of the last century. It is characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres.

said Klaus Schwab, Founder and Executive Chairman, World Economic Forum.

The main idea is that technologies do not replace, but rather gradually complement, humans, becoming a new “tool” in the hands of business. At the moment, businesses need to prepare for 4IR to survive amid the post-pandemic crisis. What’s more, companies that can keep up with the times and gain necessary skills in advance will win the race by leveraging the new tools.

4IR for business survival

Companies successfully deploying 4IR technologies now may actually emerge as stronger competitors during a recovery, and will likely be better prepared for a potential economic downturn in the future. 4IR benefits are evident: increased productivity, efficiency and quality of processes, as well as better staff safety, data-driven decision-making, and increased competitiveness thanks to developing customized products.

According to a recent PwC survey of CFOs, while the COVID-19 crisis has led 70% of companies to cut back or defer planned investments, just 22% said their companies are curbing investments in digital transformation. What does digital transformation actually entail?

Digital transformation means preparing an organization for 4IR solutions and then systematically adopting them in the most optimal way to minimize business risks. In fact, it is an organization-specific process which should be supervised by digital transformation specialists. This very approach will help you harness and exploit 4IR.

Stages of digital transformation:

- Technology digitalization. Create advanced digital infrastructures and RPA-based systems to collect data and control processes.

- Production digitalization. This stage requires the creation of a digital platform to collect, store, and process data, use some analytics tools (machine learning, digital twins), and engage production planning and management systems using the same models and data from the digital platform.

- Digital services and apps. They are created on top of the rest to improve efficiency and performance. Data analytics tools allow for prompt and, ideally, automatic adjustment of production and technological processes, thus eventually raising product quality, reducing its cost, and improving other parameters.

How to start adopting 4IR?

As I already mentioned, each organization goes its own way here; however, there is a standard 4IR checklist.

Process automation. Whether at manufacturing facilities or in the office, process automation is one of the key success factors on the path to 4IR adoption. Process automation may include: RPA-based filling out of documentation, automated Big Data collection for subsequent analysis, automation of routine processes and procedures using artificial intelligence, video analytics, and IoT.

Big Data. All business processes are based on analytics. Indeed, data analytics helps determine a business development vector, predict critical situations, and optimize processes. A full-fledged data collection is only possible when information comes from all business process participants, from the production to the sales office or store.

Vision Zero and concern for people. Another pillar of the 4IR approach is personnel safety and care. Manufacturing enterprises adopt Vision Zero, which significantly improves occupational safety. Thus, VR drills fully immerse personnel in any possible scenarios to train them in dealing with emergencies without any risk, while Digital Worker solutions warn in advance about on-site hazards. There are also solutions to ensure office personnel safety and comfort. For example, BIM tools help adjust environmental conditions in the office, while contactless solutions prevent the spread of infections.

Business optimization. As a rule, the transition to 4IR goes along with certain internal restructuring and business optimization, which is unavoidable after adopting better and more cost-effective solutions that free up specialists time. As a result, companies can spur strategic development and planning or strengthen previously understaffed business units.