VIRTUAL HEALTH AND SAFETY TRAININGS

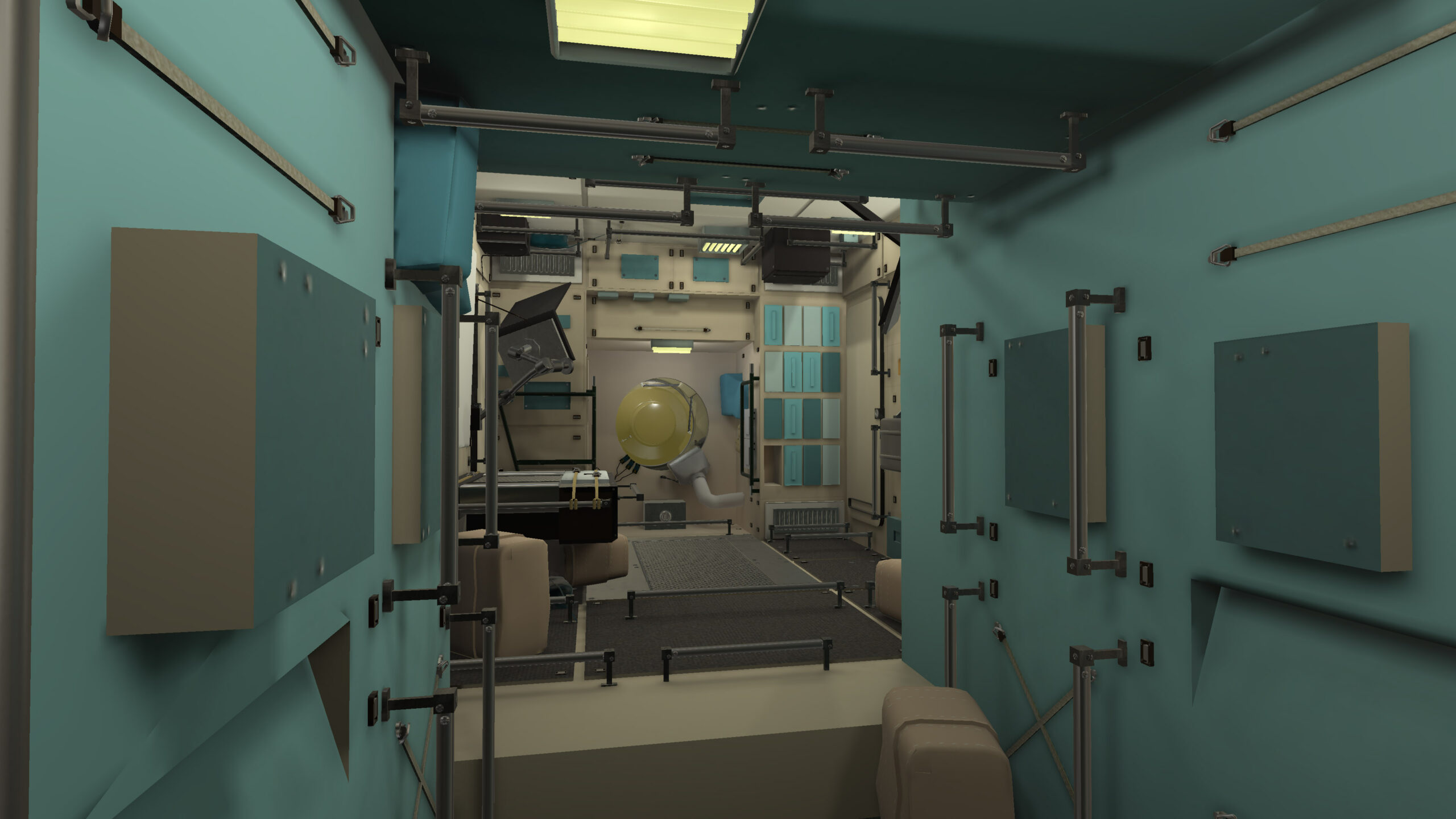

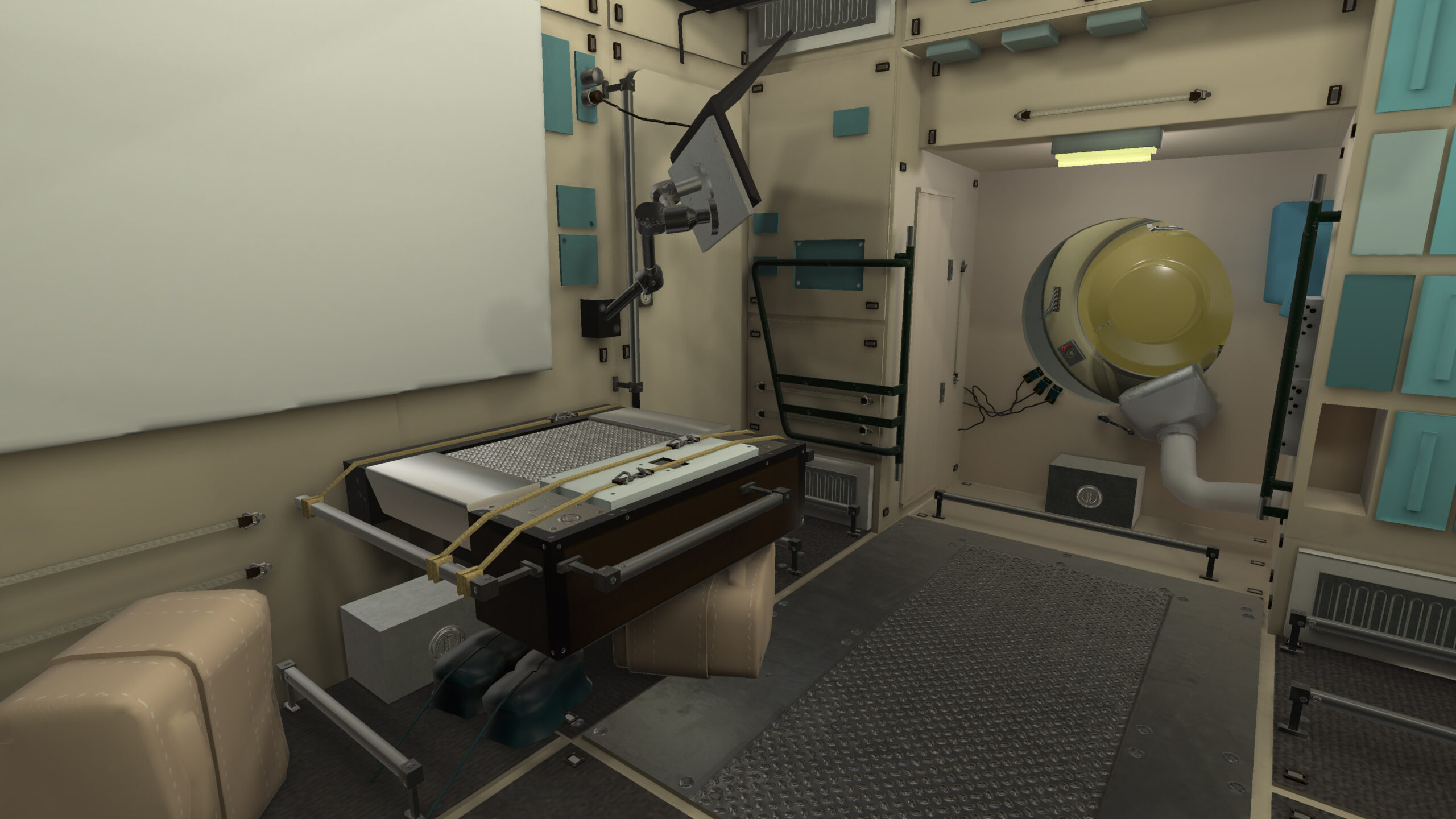

We make custom VR simulators that are used to train personnel in enterprises with increased trauma and risk. This allows personnel to learn in safe conditions in an environment that is as close to reality as possible. VR trainings emulate real-life operations and processes faced by the specialists of oil refining plants or energy infrastructure facilities in their everyday work and are a big help for the practicing of equipment maintenance procedures, emergency drills, and mastering of new skills.

In addition, NNTC can help arrange distance learning and regularly check personnel knowledge anywhere, even in hard-to-reach locations, using a VR simulator connected to a corporate Learning Management System (LMS).

Learn more about Health and Safety VR training simulators.

EXHIBITING VR&AR SOLUTIONS

NNTC helps customers effectively attract the audience and stand out at events and exhibitions. We develop custom 3D models of objects with the required level of detail, animation and infographics, and adjust 3D content for a wide variety of technologies:

- VR headsets (including VR multiuser);

- 3D/AR mobile applications;

- interactive presentations and projection screens;

- holographic installations.

Unlike providers of partial solutions, NNTC integrates products from multiple vendors to develop solutions that solve tasks of our customers in the most effective way and meet their needs. NNTC closely works with Unity, Vive, Oculus, Unreal Engine, Samsung Gear VR, Unigine, Vicon and other vendors.

PRESENTATION

DIGITAL MODEL

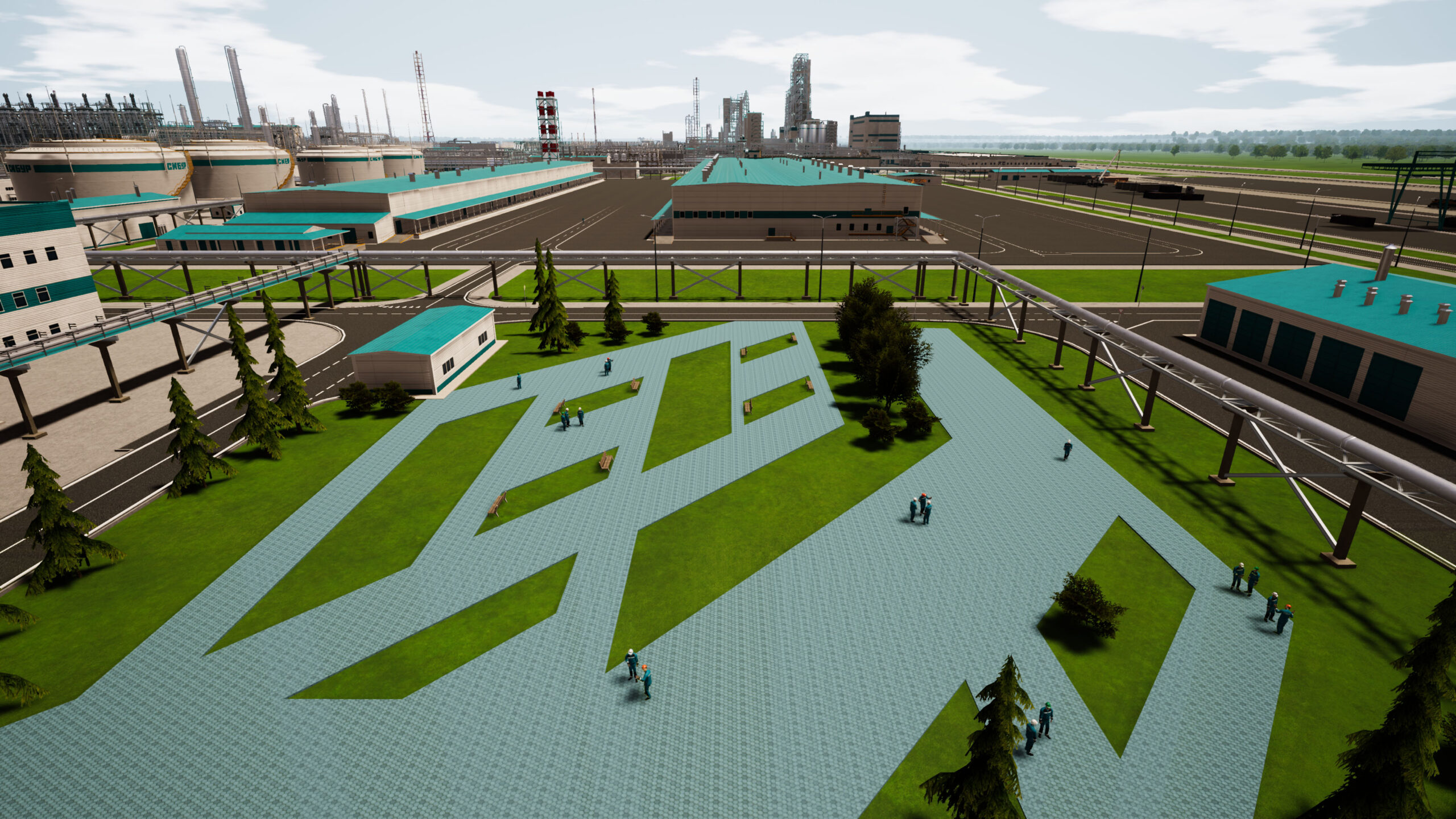

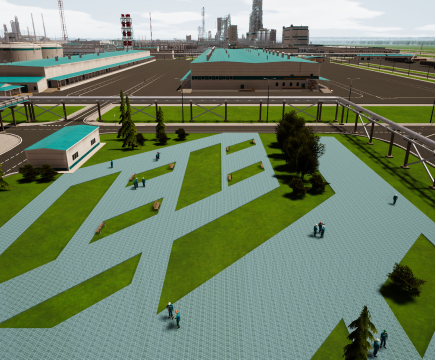

Industrial digital transformation (Industry 4.0) leads to the creation of cross-technology projects. NNTC’s VR solutions for Industry 4.0 combine our expertise in integrated digitization of industrial facilities and operations with the tools to visualize information from sensors.

Here, we came up with the concept of Digital model that exactly reproduces production processes, facilities and infrastructure of an enterprise. Digital model – it is the first step to your digital enterprise.

The digital model can help corporate university specialists train new employees, visualize production facilities and processes, and improve occupational and industrial safety. Giving a big picture of the enterprise, the digital model can help develop evacuation plans, as well as optimize production chains during the operation of industrial assets.

How different stakeholders in organization benefit from Digital model:

- Business development managers – a handy tool for demonstrating facility to potential investors.

- Corporate University – a digital platform for training new employees, service engineers, and operators.

- Technologists and design engineers – a modern tool for monitoring and tracking of technological processes. Animation and interaction with content enable a more accurate assessment of the designed process, as well as demonstration of the process to management and invited delegations without a need for deep understanding of the technology.

- Health and Safety Executive (HSE) – practicing emergency in a simulated virtual environment for expeditious escape in case of fire, industrial breakdown, fuel leak, etc.

- Marketing & PR team – demonstration of innovative solutions during expos and exhibitions.

DIGITAL MUSEUM: VR TOUR

Using VR Headsets allows implementing various scenarios of photorealistic interactive museum tour in virtual reality with a full immersion in museum environment.

Accurate artwork digitization and museum reproduction in VR provide the following advantages:

- Interactivity. Virtual museums are free from limitations people face when visiting real-life museums. Users can now zoom in any exhibit and view it as close as they want to, rise above the statue and look behind its back, discover the tiniest details: dress pleats, hair curls, and stone texture.

- Safety. Many artworks, which have never been exhibited before, can now come back to galleries and museums in VR and AR format. Moreover, exhibit digitization is crucial for the retention of the cultural heritage: if a real-life original is damaged, its digital copy will persist.

- Wide coverage. Exhibits in AR and VR can be demonstrated worldwide and thus accessed by a wider audience.